Fully Automatic 100~500 Cbm Per Day Particle Board Multi Opening

Press Production Line

Fully Automatic 100~700 Cbm Per Day Particle Board Multi Opening

Press Production Line

Description

The 110~500 cbm/day PB production line has automatic operation

system, reasonable technical process, stable running. It can

produce 4 x 8, 6 x 8, 6 x 9,6 x12 sized PB. This production line

uses the waste of wood process factory and branches of wood as raw

material, after chipping, flaking, drying, sifting, hot-press,

sanding and cutting to produce particle board. The particle board

can be used for furniture, building construction, package, inner

decoration of vehicle and ship, and short-cycle over-laying

particle board for decoration.

The multi-daylight hot pressing lines with 2 or 3 layers provide

for the simultaneous loading into the press of multiple panels by

means of a multi-level automatic loader.

Different sizes, specific pressure and number of daylights are

available, depending on the production needs and requirements. The

line can feature an individual multi-daylight press or as two

independent superimposed multi-daylight presses, served by a single

loader.

The second solution proves to be necessary when, for high

productivity requirements, a large number of daylights are

required. In this case, it is very advantageous to reduce the time

interval between the end of the composition and the start of the

pressing, dividing the total number of daylights into two

completely independent daylights..

A wide range of automatic devices and services for laminate

flooring with 2 or 3 layers is available: feeding systems of the

noble strips, of the support and counter-balancing panels, glue

spreading systems, various automatic systems for the coupling of

the different layers, loading and unloading of the press, cooling

and stacking devices.

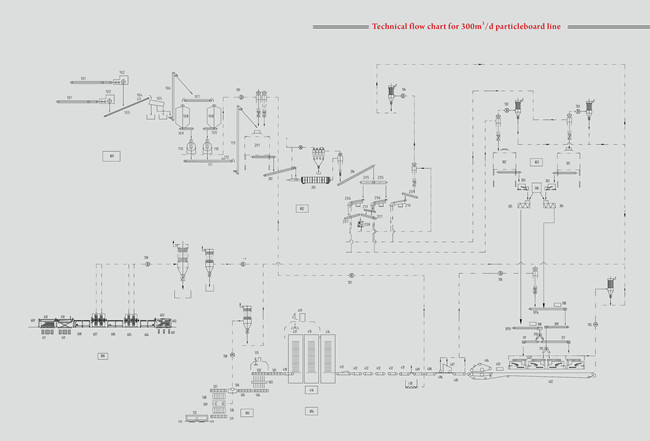

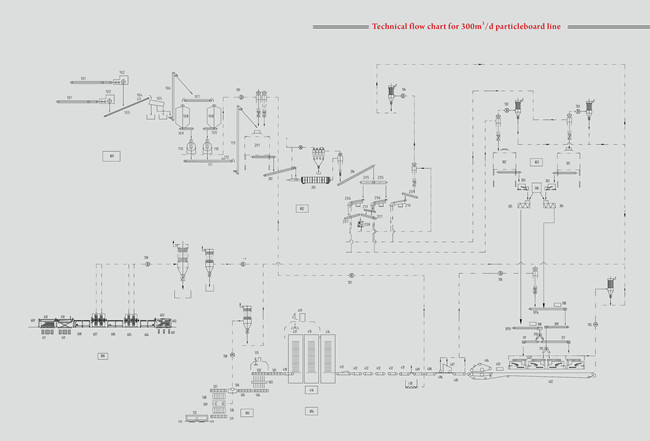

Summary of process flow

- Chips and Flakers Preparation Section

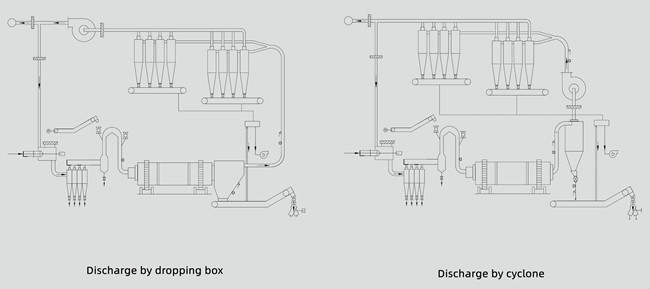

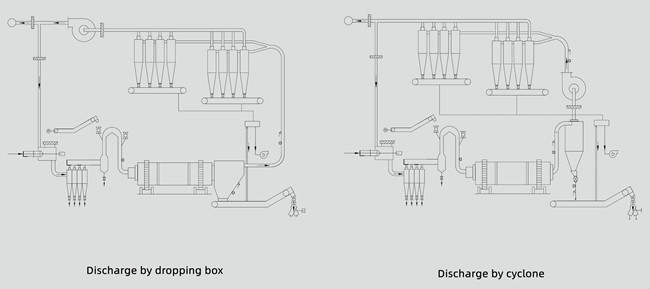

- Drying and Sifting Section

- Glue Dosing System

- Forming and Hot-Pressing Section

- Cooling and Sawing Section

- Sanding Section

Main economic and technical data

| Description | Unit | Specification | Remark |

| Annual capacity | m³ | 110 | 180 | 300 | 500 | Thickness is 19mm |

| Product specification | | | | | | |

| Board size | mm | 1220×2440 | |

| Thickness range | mm | 10~25 | |

| Density | kg/m³ | 600~750 | |

| Annual wood consumption | kg/m³ | 580~730 | Bone dry |

| Urea Formaldehyde | kg/m³ | 68~85 | Solid content 100% |

| Solid content | kg/m³ | 0.17~0.22 | |

| Paraffin | kg/m³ | 2.87~3.6 | Solid Paraffin |

| Production water | m³/h | 5 | 10 | 15 | 18 | |

| Compressed air consumption | m³/min | 6 | 10 | 12 | 14 | |

| Heat consumption | kcal/h | 300×104 | 600×104 | 1200×104 | 1500×104 | Excluding glue making |

| Power installation | kW | ~1700 | ~2500 | ~3500 | ~4000 | |

| Personnel | person | ~90 | Based on site condition |

| Yearly | days | 300 | |

| Daily shafts | shaft | 3 | |

| Daily hours | hour | 22.5 | |

| Note:the above data are subject to change according to production

process and raw material. |

Main characteristics of particle board production line

- Good adaptation of raw material: Small wood-log, branches, residue of the wood processing, can be

used as raw material for particle board.

- Lower glue consumption: The electrical measuring and adjusting of the ratio between

various materials and glue, the proportion between the flakes and

the glue can be controlled by computer system on line. High

pressure glue injection, can ensure the glue mist very well, which

is good for glue blending and lower the glue applying consumption.

- Homogeneous structure of mat: The forming machine adopts the advanced mechanical

classic-forming, with special diamond roller, to ensure ideal

spreading, improve the board quality in the end.

- Hot-pressing system: Adopting multi-opening press, ensure the press closing synchronal

by both mechanical and hydraulic methods. The board thickness

tolerance is less, in order to reduce sanding amount.

- High efficiency automatic control: The whole electrical control system of the production line adopts

world advanced electrical elements, the control system work

reliably and stably.

Key equipment of production line