Automatic Sanding Machine Sander For MDF, Particle Board, Chipboard

Technical features of V-sanding machine

- Multiple modules and multiple speed range to cater to different

types of sanding subject;

- Angle sanding, floating sprint system, polishing, laser thickness

measurement;

- Direct drive of contact drum roller to yield high transmission;

- Separate driving system for top and bottom feeding system;

- Optimized dust collection system design with constant air

compensation;

- Perfect dia.-to-thickness ratio of contact drum roller;

- Seamless eccentric device for contact drum roller;

- Modular design to ensure easy combination and upgrade;

- Comprehensive production data management system;

- Beautiful industrial outlook design.

Technical features of V4i-wide belt sanding machine

- Designed for super-thin board (~1.6mm) and high speed (~150m/min)

sanding;

- Reinforced structure design of the main frame, golden

diameter-to-thickness ratio of the contact roller, less vibration

leads to less mark in the board surface;

- Multiple sanding setting available, i.e. top-backward and

bottom-forward, front-forward and end-forward and end-backward,

top-bottom matrix, slide pad technology;

- Pneumatic clamping system and centralized feeding system achieves

smooth and stable board feeding;

- Centralized lubrication system makes easy for machine maintenance;

- Informatization control system manages equipment, output and

consumption;

- Digital automation technology available, i.e. sanding head servo

adjustment, sanding belt self-tracking system, sanding belt linear

adjustment system.

Main technical specifications

1. Multiple modules available

2. Super rigidity frame

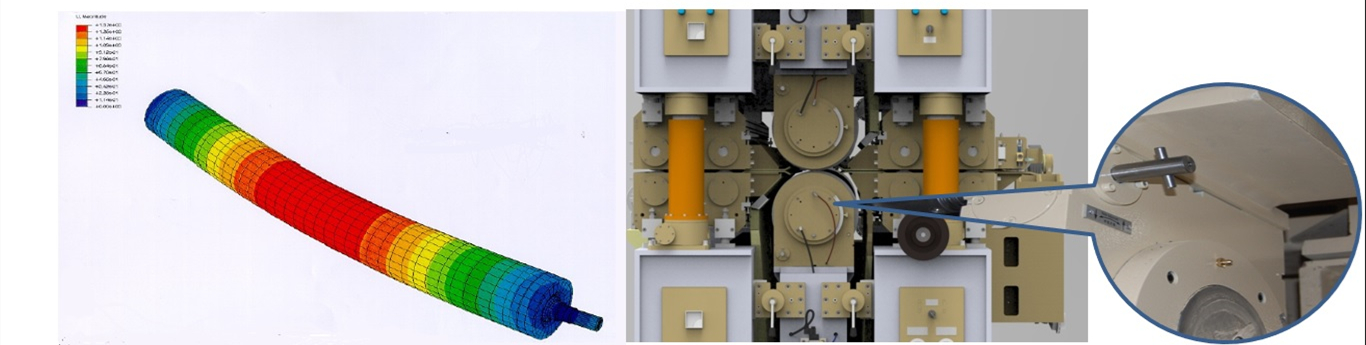

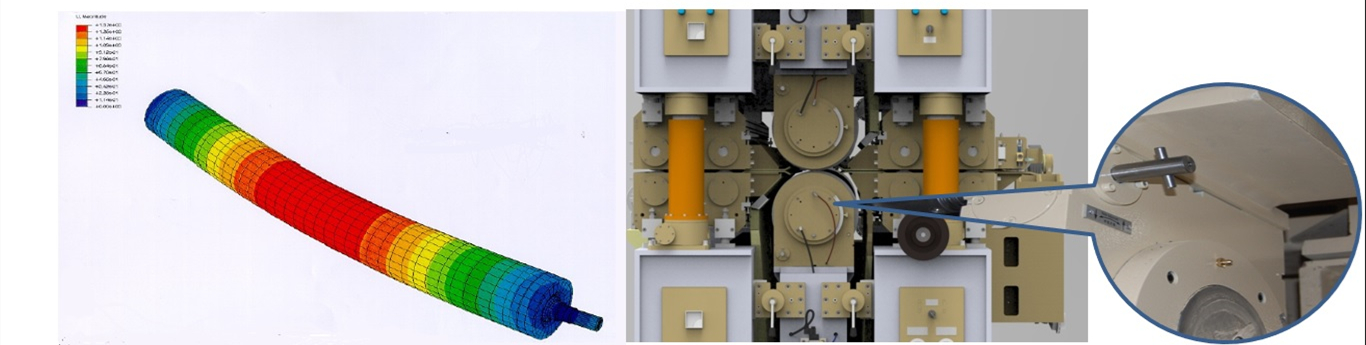

1) Cantilever beam precise control based on finite element model;

2) Advanced frame stress relief treatment;

3) High precision locking device

3. High interchangeable modular design

4. Contact drum roller

1) Big diameter contact roller with seamless eccentric device to

ensure high running precision;

2) Special surface treatment of the drum roller;

3) Easy one-side adjustment of the contact drum roller.

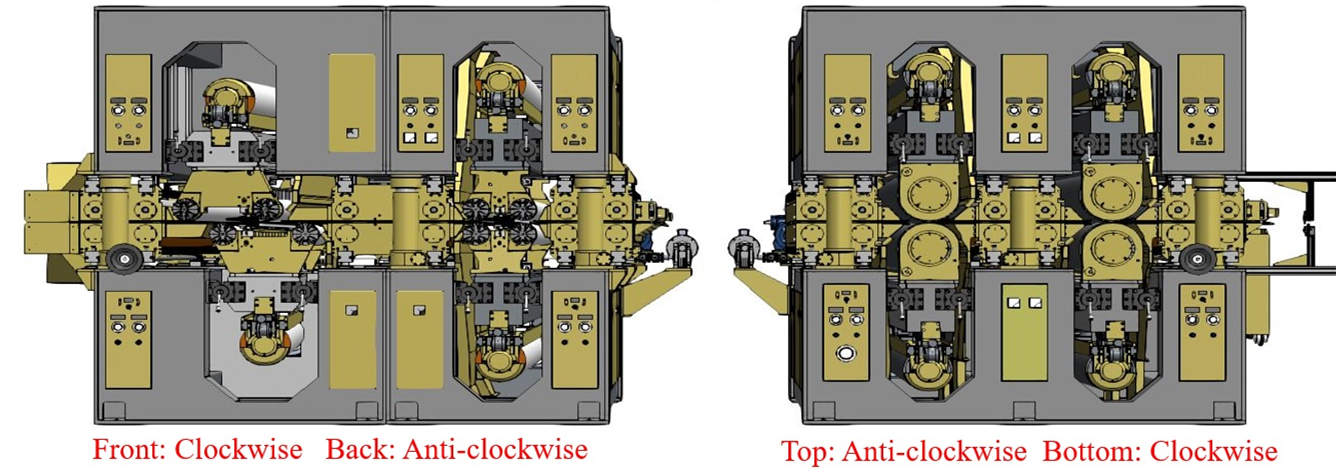

5. Sprint system

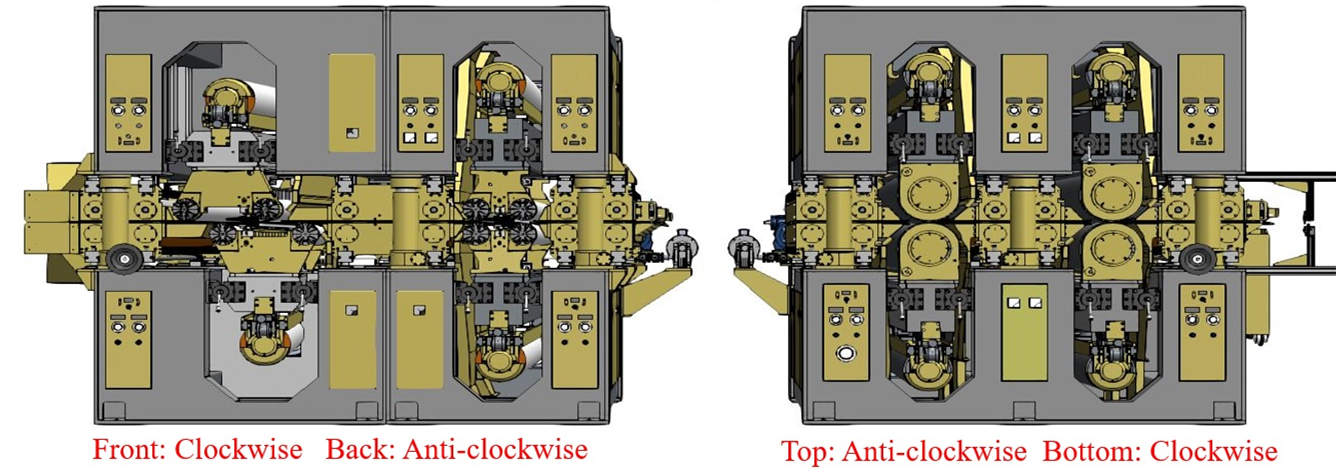

1) Combination of clockwise sanding and anti-clockwise sanding;

2) Angle Sprint system;

3) All-inclusive finishing effect and uniform surface quality.

6. Polishing head

The polishing head with Non-woven cloth roller from 3M company

gives a perfect finishing of the board with equal sanding effect of

180-240 grit sanding belt, but saving electricity cost up to 80%.

7. Highly efficient transmission

8.Dual air cell tension device to offset circumference tolerance of

sanding belt

9. Highly efficient transmission with low heat generation; Pneumatic clamp feeding system

10. Mechanical lifting

11. Triple blocking for multiple board feeding

1) Laser thickness measurement;

2) Microswitch;

3) Blocking blade plate.

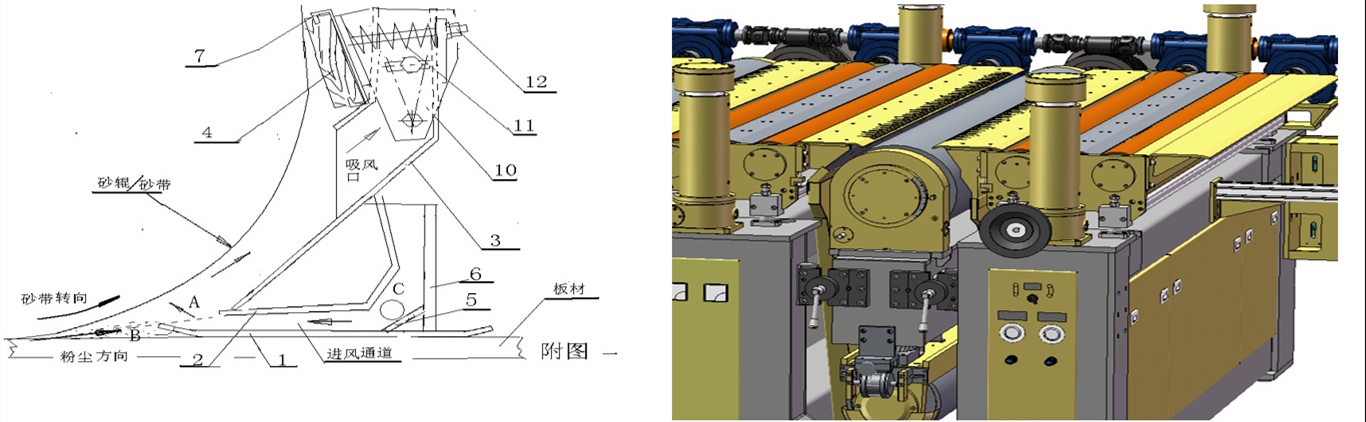

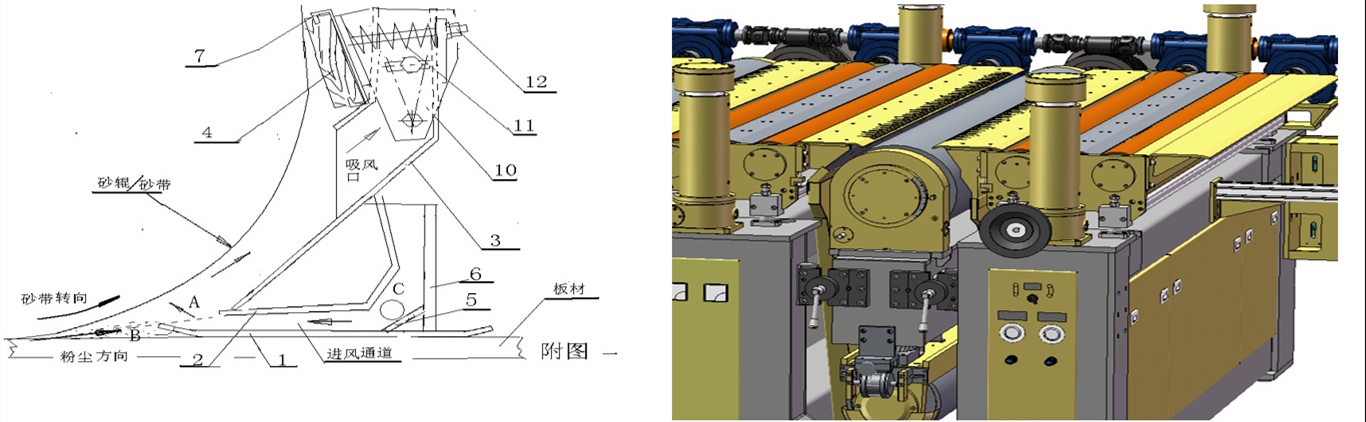

12. Dual suction opening in the dust removal system; Constant air compensation

13. Intelligent control system

1) Mainstream PLC with HMI, Profibus Communication;

2) Monitoring device: Temperature, vibration (Optional) Linear

speed, Trend analysis, Malfunction diagnosis.

Main data

| Parameters | Unit | BSG_V-13 | BSG_V-16 |

| Board Width | mm | 1300 | 1600 |

| Thickness range | For multiple opening press | mm | 3~50 | 3~50 |

| For continuous press | mm | 2~50 | 2~50 |

| Working tolerance | mm | ±0.05 | ±0.05 |

| Feeding speed | For multiple opening press | m/min | 6~50 | 6~50 |

| For continuous press | m/min | 2~90/120 | 2~90/120 |

| Opening of upper frame | mm | 280 | 280 |

| Sanding belt linear speed | m/s | 22~33 | 22~33 |

| Sanding roller motor | kW | 75/90 | 90/110 |

| Combined decks motor | kW | 55 | 55/75 |

| Fine sanding motor | kW | 55 | 55 |

| Incline fine sanding motor | kW | 45 | 55 |

| Polishing motor | kW | 18.5 | 18.5 |

| Sanding belt width | mm | 1350 | 1650 |

| Compressed air consumption | m³/h | 4~7 | 4~7 |

| System pressure | MPa | 0.6 | 0.6 |

| Technical parameters | Unit | BSG_V4i-19 | BSG_V4i-23 | BSG_V4i-26 | BSG_V4i-29 |

| Max.working width | mm | 2000 | 2300 | 2600 | 2900 |

| Thickness range | mm | 1.6~50 | 1.6~50 | 1.6~50 | 1.6~50 |

| Feeding speed(servo adjustment) | m/min | 6-50

10-90

20-150 | 10-90

20-150 | 10-90

20-150 | 10-90

20-150 |

| Opening of upper frame | mm | 300 | 300 | 300 | 300 |

| working tolerance | mm | ±0.075 | ±0.075 | ±0.075 | ±0.075 |

| Main motor | kW | UP to 132 | UP to 160 | UP to 160 | UP to 160 |

| Feeding motor | kW | UP to 22 | UP to 30 | UP to 30 | UP to 30 |

| Abrasive belt size | Roller type frame size

(width x length) | mm | 2050x3250 | 2350x3250 | 2350x3250 | 2650x3250 |

| Combined/fine sanding frame(width x length) | mm | 2050x3250 | 2350x3250 | 2350x3250 | 2650x3250 |

| Dust discharge air volume | Roller Sand Frame | m³/h | 12800 | 15000 | 17000 | 19000 |

| Combined head | m³/h | 10000 | 12400 | 14000 | 16500 |

| Fine sanding head | m³/h | 10000 | 12400 | 14000 | 16500 |

| Cleaning device | m³/h | 2700 | 3100 | 3500 | 3900 |

| System pressure | Mpa | 0.6 | 0.6 | 0.6 | 0.6 |

| Compressed air | m³ | 4~7 | 4~7 | 4~7 | 4~7 |

| Equipment weight | t | 22~39 | 24~43 | 26~45 | 28~48 |